| Manufacturer | ARCCAPTAIN |

|---|---|

| Place of Business | ARCCAPTAIN |

| Part Number | ARCCAPTAIN Soldadora |

| Parcel Dimensions | 53 x 45 x 43 cm; 23.36 kg |

| Item model number | ARCCAPTAIN Soldadora |

| Power Source | dc |

| Included Components | MIG205MP |

| Batteries Required? | No |

| Item Weight | 23.4 kg |

| Country of origin | China |

ARCCAPTAIN 9 in 1 MIG Welder APP Control Plasma CutterARCCAPTAIN

Image Unavailable

Image not available for

Colour:

Colour:

-

-

-

- To view this video, download

-

-

-

-

-

-

-

VIDEO

VIDEO -

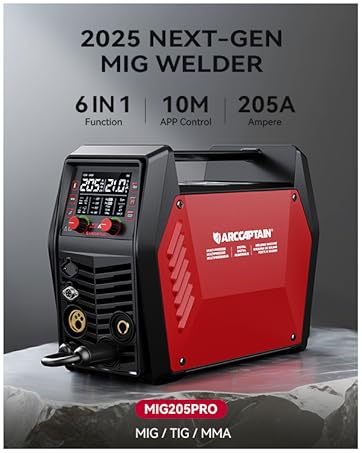

ARCCAPTAIN MIG205MP MIG Welder, 9 in 1 iControl APP Control Plasma Cutter/Pulsed MIG/Flux Core/Spool Gun/DC HF/Lift TIG/Clean/Stick Aluminum Welding Machine 120/240V Dual Voltage Multiprocess Welders

50+ bought in past month

To see product details, add this item to your cart. You can always remove it later.

Coupon:

Apply $150 coupon Terms Delivery & Support

Select to learn more Ships from

�鶹��

�鶹��

- You will be able to track your �鶹�� order from point of shipping to your doorstep in your orders. If you need more help with tracking your package, please visit Track Your Package.

- Learn more

Eligible for Return, Refund or Replacement within 30 days of receipt

- This item can be returned in its original condition for a full refund or replacement within 30 days of receipt.

Customer Support

Fixing things is quick & easy.

Our specialist Customer Support for large items dispatched from �鶹�� is on hand to help with your order. Contact us via phone or chat 7 days a week.

Our specialist Customer Support for large items dispatched from �鶹�� is on hand to help with your order. Contact us via phone or chat 7 days a week.

Purchase options and add-ons

- 9-IN-1 WELDER:ARCCAPTAIN MIG205MP MIG welder has 9 welding modes: Gas MIG/Gasless MIG/Cut/DC HF TIG/DC Lift TIG/MMA Stick/Clean/Spot Welding/Spool Gun Aluminum Welding (Need to buy extra spool gun). This multiprocess welder perfectly handles all your needs—from home DIY and garage projects to outdoor repairs, farm equipment, and road maintenance and repairs.

- APP CONTROL & MEMORY FUNCTION: ARCCAPTAIN 2025 flagship design, enables parameter adjustment, real-time monitoring, and status detection within a 10-meter range. Featuring unlimited preset memory, users can save and name custom settings via the app. The app also includes an FAQs section, providing instant access to troubleshooting guides and solutions from our knowledge base.

- LARGE LED DISPLAY & SYN FUNCTION: Features a large LED screen for clear visibility of welding parameters and settings, ensuring intuitive operation. The welder's smart parameter-matching system automatically adjusts current and voltage based on your selected metal type/electrode size—making it beginner-friendly while improves work efficiency.

- TECHNICAL UPGRADE: The MIG205PM welder now offers advanced parameter control for experienced users, including adjustments for MIG (Inductance, Burn-back, welding speed, etc.), TIG (pulse frequency, Initial current, Descent time, Finish time, etc.), and MMA (Hot start, Arc force, etc.) functions, while its dual-voltage design (120V/240V) allows flexible power switching (Note: Ensure the screen is off and the fan has stopped before voltage switching).

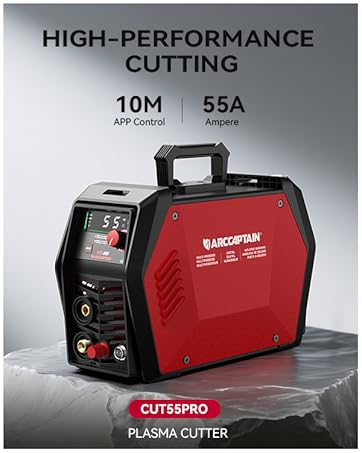

- HIGH PERFORMANCE WITH VERSATILITY: Rated duty cycle:60%. Welding Current: MIG:30-205A; TIG/MMA:20-205A; Clean:20-40A; Cut:20-50A; Cutting thickness: Quality 12mm (1/2"), maximum 18mm (2/3"). It supports both Lift TIG/HF TIG torches (shared to reduce costs) and is compatible with foot pedals for enhanced control.

- 2 YEARS QUALITY SERVICE & SAFETY: Our technical personnel will resolve your problem promptly. Equipped with dual cooling fans for enhanced heat dissipation efficiency. Includes VRD functionality, fault alarm systems, and comprehensive protection against overcurrent, overvoltage, overload, and overheating.

Frequently bought together

This item: ARCCAPTAIN MIG205MP MIG Welder, 9 in 1 iControl APP Control Plasma Cutter/Pulsed MIG/Flux Core/Spool Gun/DC HF/Lift TIG/Clean/Stick Aluminum Welding Machine 120/240V Dual Voltage Multiprocess Welders

$1,299.99$1,299.99

Get it by Sunday, Jan 18

In Stock

$269.99$269.99

Get it by Sunday, Jan 18

In Stock

$104.99$104.99

Get it by Sunday, Jan 18

In Stock

Total price:��$00$00

To see our price, add these items to your cart.

Try again!

Added to Cart

Add all 3 to Cart

Choose items to buy together.

Videos for similar products

From the brand

-

-

-

-

-

-

-

iControl Prowelder Series

-

MIG/TIG/ARC Welder & CUTTER

-

Cost-effective Welding Machine

-

-

-

Welding Accessories

-

MIG Welding Wire

-

Various Designs, Various Needs

-

Provide Sturdy & Easy Welding

-

Provide Comprehensive Safety

Product information

Technical Details

Additional Information

| ASIN | B0F37X2XQ4 |

|---|---|

| Customer Reviews |

5.0 out of 5 stars |

| �鶹�� Rank |

|

| Date First Available | April 1 2025 |

Feedback

Sponsored

$241.99

$775.99

$279.99

Product summary presents key product information

Keyboard shortcut

Shift

+

Alt

+

opt

+

D

Product Summary: ARCCAPTAIN MIG205MP MIG Welder, 9 in 1 iControl APP Control Plasma Cutter/Pulsed MIG/Flux Core/Spool Gun/DC HF/Lift TIG/Clean/Stick Aluminum Welding Machine 120/240V Dual Voltage Multiprocess Welders

From ARCCAPTAIN

About this Item

- 9-IN-1 WELDER:ARCCAPTAIN MIG205MP MIG welder has 9 welding modes: Gas MIG/Gasless MIG/Cut/DC HF TIG/DC Lift TIG/MMA Stick/Clean/Spot Welding/Spool Gun Aluminum Welding (Need to buy extra spool gun). This multiprocess welder perfectly handles all your needs—from home DIY and garage projects to outdoor repairs, farm equipment, and road maintenance and repairs.

- APP CONTROL & MEMORY FUNCTION: ARCCAPTAIN 2025 flagship design, enables parameter adjustment, real-time monitoring, and status detection within a 10-meter range. Featuring unlimited preset memory, users can save and name custom settings via the app. The app also includes an FAQs section, providing instant access to troubleshooting guides and solutions from our knowledge base.

- LARGE LED DISPLAY & SYN FUNCTION: Features a large LED screen for clear visibility of welding parameters and settings, ensuring intuitive operation. The welder's smart parameter-matching system automatically adjusts current and voltage based on your selected metal type/electrode size—making it beginner-friendly while improves work efficiency.

- TECHNICAL UPGRADE: The MIG205PM welder now offers advanced parameter control for experienced users, including adjustments for MIG (Inductance, Burn-back, welding speed, etc.), TIG (pulse frequency, Initial current, Descent time, Finish time, etc.), and MMA (Hot start, Arc force, etc.) functions, while its dual-voltage design (120V/240V) allows flexible power switching (Note: Ensure the screen is off and the fan has stopped before voltage switching).

- HIGH PERFORMANCE WITH VERSATILITY: Rated duty cycle:60%. Welding Current: MIG:30-205A; TIG/MMA:20-205A; Clean:20-40A; Cut:20-50A; Cutting thickness: Quality 12mm (1/2"), maximum 18mm (2/3"). It supports both Lift TIG/HF TIG torches (shared to reduce costs) and is compatible with foot pedals for enhanced control.

- 2 YEARS QUALITY SERVICE & SAFETY: Our technical personnel will resolve your problem promptly. Equipped with dual cooling fans for enhanced heat dissipation efficiency. Includes VRD functionality, fault alarm systems, and comprehensive protection against overcurrent, overvoltage, overload, and overheating.

Product description

MIG205MP MIG WELDER 9-in-1 Welder Machine 110V 220V

Feedback

Did you find this product summary feature useful?

Yes, it is useful

No, it is not useful

Thank you for your feedback

Thank you for your feedback. You selected “Yes, it is useful”

Thank you for your feedback. You selected “No, it is not useful”

Change your feedback

![ARCCAPTAIN iControl Cut55 Pro Plasma Cutter, [APP Control] 55 Amp Non-Touch Pilot Arc 110V/220V P...](https://m.media-amazon.com/images/S/aplus-media-library-service-media/7dff8ad8-7669-4397-ab6f-e5e2f83066b5.__CR0,0,498,546_PT0_SX166_V1___.jpg)

![ARCCAPTAIN iControl ARC205 Pro Stick Welder, [APP Control] 165Amp ARC/Lift TIG Welding Machine](https://m.media-amazon.com/images/S/aplus-media-library-service-media/0fce561a-1d95-401d-8abd-b272bc10c514.__CR0,0,498,546_PT0_SX166_V1___.jpg)

![ARCCAPTAIN Stick Welder, [Large LED Display] 200A ARC/Lift TIG Welding Machine with Synergic Cont...](https://m.media-amazon.com/images/S/aplus-media-library-service-media/1600bf78-74bc-49b8-ae5a-77a38a62ef72.__CR0,0,498,546_PT0_SX166_V1___.jpg)

![ARCCAPTAIN Plasma Cutter, [Large LED Display] 50Amps Plasma Cutter Machine with 110/220V Dual Vol...](https://m.media-amazon.com/images/S/aplus-media-library-service-media/3821a4b6-00e7-41e7-8e3d-28bd0a455fab.__CR0,0,498,546_PT0_SX166_V1___.jpg)